San Fang have been the artificial leather leader in the industry

for over 40 years. We have 27 years of experience making fiber

for our non-woven product, and have expanded into selling yarn

to brands and textile suppliers since 2015. We have focused on

making high quality and functional yarn for the various industry,

with improved physical properties and more sustainable practices.

Our dope dye polyester and TPU yarn both save water and energy

compared to standard/traditional dyed yarn.

The textile dyeing and finishing industry has created a huge pollution problem as it is one of the most chemically intensive industries on earth, and the No. 1 polluter of clean water (after agriculture). More than 3600 individual textile dyes are being manufactured by the Industry today. The industry is using more than 8000 chemicals in various processes of textile manufacture including dyeing and printing. Many of these chemicals are poisonous and damaging to human health directly or indirectly. Large quantities of water are required for textile processing, dyeing and printing. The daily water consumption of an average sized textile mill having a production of about 8000 kg of fabric per day is about 1.6 million liters. The overall water consumption of yarn dyeing is about 60 liters per kg of yarn. Dyeing section contributes to 15% - 20% of the total waste water flow. Water is also required for washing the dyed and printed fabric and yarn to achieve washing fastness and bright backgrounds. Water is also required for washing the dyed and printed fabric and yarn to achieve washing fastness and bright backgrounds. Washing agents like caustic soda based soaps; enzymes etc. are used for the purpose. This removes the surplus color and paste from the substrate. The World Bank estimates that 17 to 20 percent of industrial water pollution comes from textile dyeing and finishing treatment given to fabric. This represents an appalling environmental problem for the clothing and textile manufacturers.

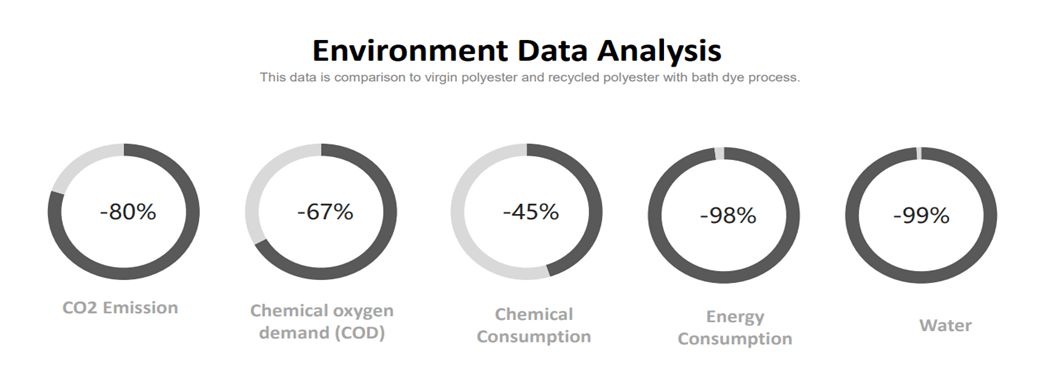

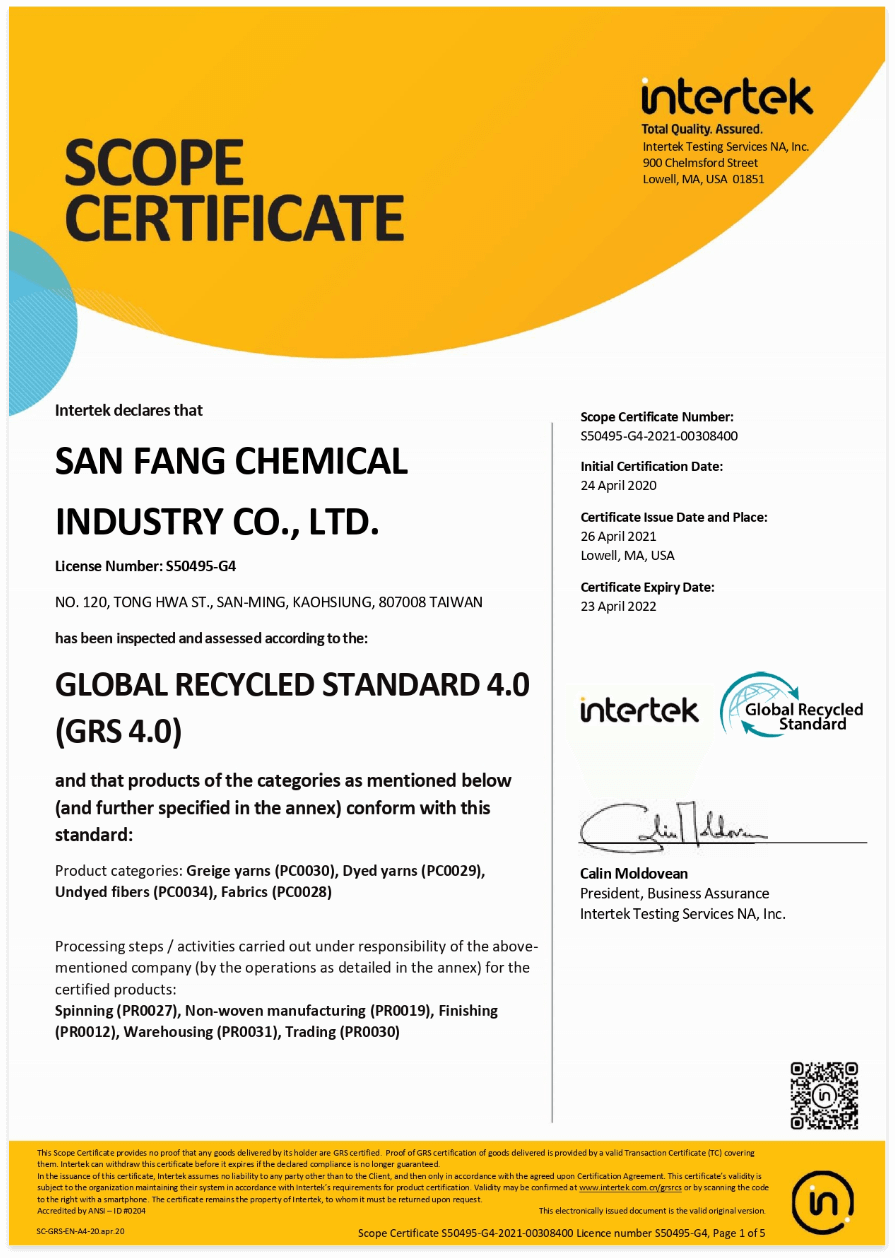

As a patnert in the textile industy, we commit to operating in a way that creates progress towards the trend of sustainability. To guide the way we work with that, we are committed to responsible consumption and production by reducing the material footprint of the products we purchase and supply. Profios® serise, is recycled from post consumer wastes of PET bottles, and its dope dyed technology is 100% water-free envirenmetally process. This process results in 99% water savings compared to traditional water dyeing . Otehr than that, in dope dyeing, the colour pigments become part of the fiber, improving the colour-fastness and leading to less colour deviation compared to fibers coloured with traditional dyeing methods. Due to the fact that production technology with masterbatch is a sustainable and environmentally friendly approach to the coloration and functionality of textiles, it is expected to see more demand in the coming years.

Profios® - PET multi yarn

Profios® serise include various spec with type of yarn.

Profios can be applied to Tricot, knitted goods, and wovens,

and are suitable for developing footwear, apparel, back pack

and home textil. We have focused on making smaller batch

sizes for the sport industry, with resonable MOQ

reqyiermentt for flexible practices. Profios is your sustaibale

and innovative choice.

| Product | Material | Yarn type | Specs (Den/Fil) |

| EF-000 | Polyester (PET) | Partially Oriented Yarn (POY) | 75D/36F 100D/36F 150D/48F 300D/96F |

| EF-100 | Fully drawn yarn (FDY) | ||

| EF-200 | Draw textured yarn (DTY) | ||

| EF-000R | Recycled Polyester (rPET) | Partially Oriented Yarn (POY) | 75D/36F 100D/36F 150D/48F 300D/96F |

| EF-100R | Fully drawn yarn (FDY) | ||

| EF-200R | Draw textured yarn (DTY) |

Profios® - NM

Even Though dope dye process can improve color fastness for

the yarn. However, there is risk on the fluorescent/ dark colord

yarn, due to the duestuff in the color masterbatch. To overcome

it, we developed an innovative techolony sussefully for these

colors, which is Profios® NM serise.

Profios® NM serise serise it is not by adding additives nor

additional chemical treatments being applied to the yarn. It was

adjusting their manufacturing process in order to lock the color

master batch inside the yarn, so the colors has no direct contacts

to be exposed.

| Product | Material | Yarn type | Specs (Den/Fil) |

| NM-200 | Polyester (PET) | Fully drawn yarn (FDY) | 150D/48F 300D/96F |

| NM-200R | Recycled Polyester (rPET) | Fully drawn yarn (FDY) | 150D/48F 300D/96F |

Profios® - EM (Polyester mono)

Profios® - PET mono yarnFor industrial or footwear application,

Profios® - PET mono yarn is your sustainable choice.

| Product | Material | Yarn type | Specs (Den) |

| EM-100 | Polyester (PET) | Fully drawn yarn (FDY) | 120D 150D 350D |

| EM-100R | Recycled Polyester (rPET) | Fully drawn yarn (FDY) | 120D 150D 350D |